Industry 4.0: The Ultimate Guide

02-08-2019 Innovation

Industry is changing a lot these days.

New concepts and systems pop-up continuously, and due to companies’ need to implement the best technology, a lot of things will change in a relatively short span of time.

One of the new terms that appeared at the turn of this decade was Industry 4.0.

As the name suggests, it is used to describe the fourth industrial revolution. The concept refers to the implementation of high-tech and, in particular, digital transformation.

So what kind of high-tech, you might be asking?

Industry 4.0 specifically focuses on smart factories that rely on the Internet of Things. It would affect every industrial process from manufacturing to logistics and supply chains.

And it will also largely affect the way we create and distribute information.

The main benefit of an Industry 4.0 system is the ability to create decentralized decision making without relying on the traditional type of physical approach.

There are a lot of different industries that can benefit from Industry 4.0. However, it has shown the best results for:

- virtual and augmented reality

- robotics

- energy

- specific types of goods

- autonomous or remote-controlled vehicles

In this article, I will discuss some practical steps that will help you implement Industry 4.0.

But let’s move forward one step at a time and see how it all started. Read on!

Photo by Franck V. on Unsplash

The first mention of the term Industry 4.0

If you think that the birth of Industry 4.0 has to do with the private sector, you would be dead wrong.

The term was initially introduced by the German government in their attempt to promote digitisation. Their version was “Industrie 4.0” or simply “I4”.

It was used during the Hannover Fair in 2011. Something that initially started as a great idea quickly turned into action: The German government created a working group in 2012 that was meant to create guidelines which would then be implemented at a federal level.

The working group was spearheaded by Siegfried Dais (Robert Bosch GmbH) and Henning Kagermann (German Academy of Science and Engineering). In April 2013, the project was ready.

Given that the concept is relatively new, it is still being modified and improved. There is a lot of discussion as to how to further polish it so it can benefit everybody.

There are also a lot of economic, political and social challenges that need to be addressed which we will discuss in the following chapters, so make sure you stick around!

Industry 4.0’s impact on the market

Not everyone wanted to implement I4.

While the concept works amazingly for bigger systems, it might not be ideal for smaller enterprises. Its effect will also vary from industry to industry.

Nevertheless, Industry 4.0 can bring amazing results to the companies that implement it.

There are also those who are unwilling to make the shift due to preconceptions or conservatism. However, as we go forward, it seems that Industry 4.0 will not only represent a small technical benefit, but it will become a necessary requirement to stay in business.

We recognize 6 dimensions of Industry 4.0:

- Strategy and Business Model (Creating the right strategy that will benefit from this concept)

- Technology and Systems (Using technology for optimal results)

- Governance and Risk Management (Getting the most from the concept while avoiding risks)

- People (Educating and leading employees so they can adapt to the new industrial norm)

- Operational Excellence (Gaining a competitive edge through technology)

- Customer Experience (Further improving customer experience)

Depending on the author, these dimensions may vary.

Still, they will almost always refer to processes that are otherwise common for traditional businesses.

What are the 3 main end benefits of Industry 4.0?

- Improved productivity

- Reduced costs

- Process automation

If we exclude the initial implementation costs, there are very few drawbacks to I4. It is a concept that keeps on giving and the sooner you implement it, the sooner you will see its benefits.

The 9 Pillars of Industry 4.0

Industry 4.0 is a very complex subject.

So, it is not surprising that it’s based on 9 main pillars (you can also call them elements).

Here they are:

1 Big Data and Analytics

Big data is crucial for any corporation. It refers to datasets that have a major impact on how a company forms its strategies and runs its day-to-day operations.

By improving this concept, the company is able to achieve a competitive edge. Like most business concepts, it is based on monitoring and measuring results, and then finding the right solutions. The main focus of analytics lies in dataset analysis.

Based on this analysis, the company can learn more about customer preferences and current market trends. Big data can also be used for risk mitigation. Bosch was able to use big data as a way of digitally transforming their company.

They were able to connect their machinery in order to have a better oversight of their manufacturing. With this, not only are they able to monitor the performance of individual machines and systems but they are also able to discover if there are any issues.

This way, they were able to maximize the output of their machinery which led to a 10% overall increase in productivity. At the same time, Bosch was able to improve their customer satisfaction rate. For example, in this case study, scientists were able to create a risk map regarding Rift Valley Fever:

See: NAP.edu

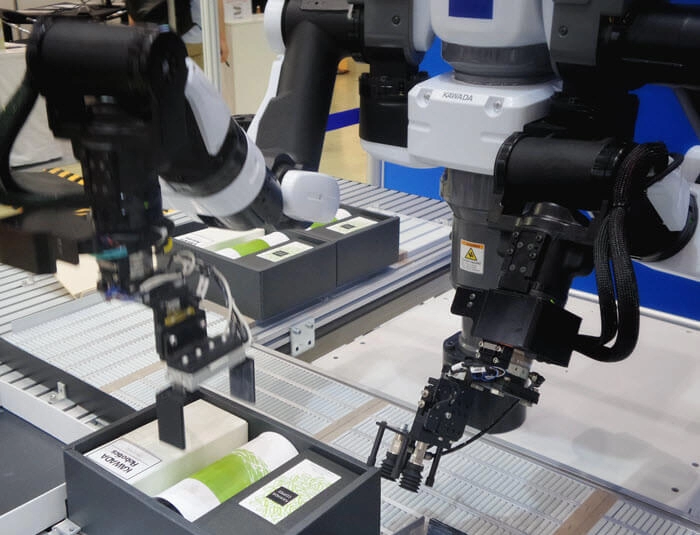

2 Autonomous Robots

Robots are not a new concept; they have existed for quite a while. However, we were never able to implement them on a larger scale and furthermore, robots of the past weren’t as autonomous as the ones we can buy today. When it comes to industrial use, robots are able to solve certain tasks that are beyond human reach.

Today, it is much easier to implement them as a part of the production process.

But that doesn’t mean that human labour will become extinct, as a worker’s input is still necessary to allow a robot to perform certain tasks. Robots can be utilized in various ways, leading to production, logistics, and distribution improvements.

Whether you like it or not, you need to use robots in order to maintain a competitive edge.

Fetch Robotics, in particular, managed to benefit from this practice. The company relies on their own line of robots, which they named Autonomous Mobile Robots.

They use them for inventory management and in particular, locating and moving things. The best thing yet is the fact that these robots are able to work by themselves, while also learning along the way. Because of them, Fetch Robotics managed to reduce their order cycle time by 50%.

However, this is only the tip of the iceberg as we don’t yet understand the full potential of autonomous robots. According to this study, today there are approximately 2.9 million robots utilized in various industries:

See: IFR.org

3 Simulation

Simulation tools are very important for their support role. They are able to self-configure enabling effective shop-floor management. Simulations are crucial nowadays as they allow companies to make predictions regarding their potential actions.

In other words, by making simulations of certain operational activities, you can learn where things may go wrong and how to prepare for such occurrences.

Alternatively, you can adjust for them beforehand thus increasing productivity or reducing costs. You can also use simulation tools to increase the productivity of your workforce according to this study, as employees are quickly getting results of their actions and can change their behavior accordingly:

See: epsteineducation.com

4 Horizontal and Vertical System Integration

Let’s start by explaining what these two terms mean. Vertical integration is used to describe adaptable systems within a production plant. On the flipside, horizontal integration deals with the integration of partners within the SCs.

During integration, the network will gather big data, which will allow for better performance. When the network gathers enough data, it will upload it onto cloud. This is where a framework will be created.

By utilizing cloud-based systems, vertical elements can be integrated with each other through the same platform. Integration can be used for almost anything. Not only is it versatile, but it is also very profitable:

See: HBR.org

5 The Industrial Internet of Things

The Internet of Things is a crucial element of this new industrial revolution. It allows devices to interact with each other, which is crucial for big systems. Each device will collect data and send it to the internet where it will be further processed.

The Industrial Internet of Things is highly dependent on a hierarchy. Lower-tier devices will gather data, whereas highly-complex devices, such as robots and medical devices, will make decisions based on that data. The Industrial IoT is important as it brings more flexibility to organizations together with more responsiveness.

Like most other technical aspects of the business, it will bring a competitive advantage to all those companies that implemented it early on. BJC HealthCare is perhaps one of the best examples of how the Industrial Internet of Things can be implemented to your advantage. As the name implies, this company operates within the health-care industry.

They rely heavily on radio frequency identification for medical supply management. With this technology, they are able to track and identify supplies without physical contact. This proved to be especially important for resupplying and tracking item expiration dates.

Previously, this job was done by people, which took forever. Also, the chance of human error was high. The company has managed to save a lot of money by having a 23% smaller inventory. According to several studies, it is predicted to generate $15 trillion of global GDP by 2030:

See: accenture.com

6 Cloud

Cloud is a crucial element that ties various pillars together. It allows transfer and storing of data as well as its further use. Most of a company’s resources will be stored there in a virtual form. The Cloud is based on three separate models: SaaS (software as a service), IaaS (infrastructure as a service), and PaaS (platform as a service).

Nowadays, clouds are so common that you don’t have to be a big corporation in order to rely on them. Even individual users can benefit from Google Cloud for example. Cloud storage is also very eco-friendly. Among other things, clouds are very popular in the automotive industry. One of the best examples of this is how Volkswagen uses them.

There are lots of ways a company can benefit from this technology, such as: having smart home connectivity, better maintenance service, regular updates, personal assistants and so on. Such systems and technology will be increasingly important in future as car makers are doing their best to create autonomous vehicles.

Large amounts of data will have to be stored and transferred which is why clouds are such a good solution to this problem. They can reduce energy consumption by 70%, making a company not only considerate towards the environment but also more financially sound:

See: sciencedirect.com

7 Additive Manufacturing

Customization has become more and more important as the years go by. Companies that are successfully meeting their clients’ needs usually have a better position in the market. This is also how we came to additive manufacturing.

Most people don’t even know what additive manufacturing refers to. This is because there is a much more common term for it: 3D printing. Besides the fact that 3D printing allows you to create customized items, it also helps you avoid mass production, which in turn leads to a big inventory and unsellable products.

On top of it all, due to its nature, 3D printing helps you use less material, which is both economically and environmentally sound. Additive manufacturing can take your whole organization to the next level. Fast Radius is one of the best examples of that. It is regarded as one of the top 9 smartest factories in the world.

The company has facilities all over the world which allows them to create customized products and quickly deliver them to almost any spot on the globe. But there is much more to this organization than simple additive manufacturing; they’ve taken the process and made it their own.

Fast Radius has developed their own platform that works well for their particular business. It is able to collect data from every part design that is stored and manufactured in the Fast Radius virtual warehouse. One of the studies found out that the component's use saves 63% of relevant energy and carbon dioxide emissions over the course of the product's lifetime:

See: sciencedirect.com

8 Augmented Reality

Augmented reality is a relatively new concept but it has already become an integral part of Industry 4.0. With it, you are able to create a false sensation and put a person into a different place.

It is a completely different type of interaction compared to anything we’ve known so far. AR creates a link between a human and a machine, putting the user in a different reality (hence the name). While it doesn’t impact business processes as much as some other pillars, it has still become a part of them.

AR allows designers to experience a product's design before completing the project. General Electric was always at the forefront of economy and industrial innovation and they have proven this by involving themselves with augmented reality.

They did a pilot project during which the productivity of workers using smart wearables increased by up to 11%, compared to the previous period.

Ultimately, this approach could offer a tremendous potential to minimize errors, cut down on costs and improve product quality. Volkswagen has used it successfully for comparing calculated and actual crash test imagery:

See: researchgate.net

9 Cyber Security

Most business is shifting online. Whether we are talking about purchasing, services, payments, or storing data, both companies and customers are highly dependent on the internet. This is why cybersecurity has become an integral part of I4.

In the last few years, the focus of cybersecurity is not only to help users and companies, but it has also become a good way to prevent cyber-crime and terrorism. Besides the fact that cybersecurity helps you protect data, these systems are also able to notice certain harmful patterns and prevent crime and terrorism before they happen.

As such, it ensures everything stays in place as it should. In fact, cyber security is so important that 66% of respondents believe that data breaches or cybersecurity exploits will seriously diminish their organization’s shareholder value according to this study:

See: raytheon.com

The biggest challenges ahead of Industry 4.0

Like every industrial revolution, there are lots of things that need to be addressed.

Due to the sheer size and global nature of I4, there are many more challenges compared to any previous industrial revolution which we’ve had in the past.

At this point, some of these challenges may seem insurmountable. Let’s see what’s ahead of Industry 4.0.

Economic challenges

High costs

The very implementation of these systems will be too high for certain companies. Besides the initial costs, you also have to consider maintenance costs over time.

Adapting the model

As previously mentioned, I4 is especially useful for bigger corporations, but it provides different results for smaller organizations. It may prove difficult creating a model that will work for all types of industry.

Productivity

While the costs may be really high, that doesn’t mean that I4 would lead to increased productivity in every situation. This is one of the reasons why it might not be economically feasible.

Political challenges

Lack of regulation

Industry 4.0 is meant to have a global character. This would make it really hard to create a framework that can be applied to all countries and systems. To make things even worse, many countries haven’t even started creating the framework which would promote I4 development.

Data breaches

The same way security is an issue for the private sector, it can be an issue for the public sector as well. If we consider the fact that I4 will be regulated by governments, and there is a high chance that the public sector will also start implementing the system, it will pose the same security threats to them as it does to private enterprises.

Other legal issues

Due to the fact that this whole area lacks regulation, it is easy to see that legal issues are not only a possibility but are to be expected. This would lead to various losses on different sides.

Social challenges

Impact on privacy

Like with everything else digital, you have to ask yourself how much will I4 affect our privacy. The more money is invested in concepts such as this, the more people will be exposed to its negative sides.

IT people losing jobs

The whole point of Industry 4.0 is to make things easier and more productive. This usually means more automation, which in turn will lead to job losses. If the whole system is expanded quickly, this will not just send shockwaves throughout the IT industry, but will affect the wider social fabric.

Disconnect with customers

Due to all of these previously mentioned factors, it is easy to see how I4 might actually have a negative impact on consumers. Ethical business models are crucial for modern companies and those who go against these policies will lose their consumers.

Trouble accepting the concept

Although I4 should represent progress compared to the system we currently have, not everyone looks at it that way. There are a lot of stakeholders who will question both the economic and the social side of it and this resistance can lead to further issues during implementation.

Challenges at the company level

Changes to the production process

Having all these systems and improved production sounds great, but that also means that current processes and machines might become obsolete. In other words, this might make certain systems, software, and machines unusable without you maximizing their potential, which in turn will lead to business losses.

Potential IT issues

Given that everything will be interconnected and managed through one system, this means that even small issues can lead to a complete breakdown. Minor IT issues will not only affect one department but the company as a whole.

Lack of qualifications

The transition period is always rocky, no matter what you are doing. In this particular case, it will be reflected through a lack of qualified employees. This would lead to further losses and a halt in production.

Protecting industrial secrets

Due to the fact that all the data will be online, companies will become more susceptible to corporate espionage and loss of business secrets and patents.

There are many challenges ahead of us, but the benefits are most definitely worth it!

How to prepare your company for Industry 4.0?

As we promised, we will now go through the preparation process and what you need to do in order to introduce I4 to your organization. Let’s dive right in!

1 What are your actual needs?

As already mentioned, not every company will profit from industry 4.0 in the same way. While certain businesses will see a significant boost in production and improvement of other industrial processes, others will take a step back. In fact, implementing I4 principles may even become a financial burden. So, make sure that you really need this and that you can maintain it financially.

2 How would it work in your particular case?

Let’s say additive manufacturing works well within your industry and your competition has benefited greatly from it. How would it work for you? In most cases, it is not only about implementation of processes, but when and where you will implement these principles.

3 Can you create a solid ‘Industry 4.0’ business strategy?

Whether you’re a big corporation or a smaller company, it is very important to create a proper strategy before implementing I4. There are lots of different risks involved in the whole process and the best you can do is to at least mitigate some of them. While you can’t do much about the legal or political aspects, you can definitely influence the financial and human factors. Each pillar needs to be addressed separately and your decisions regarding suppliers and service providers will go a long way in determining the overall success of the whole project. You should especially put emphasis on modular technological solutions.

4 How quickly and efficiently can you educate your staff?

Although Industry 4.0 sounds like a self-sustaining system, it is everything but that. Human labour is very important for maintaining some of the systems and working within these new rules. Employees will play a big role in how you’re able to adapt to changes and how quickly you can transition to this new model. In fact, you might even consider starting the training now, as you’re preparing your general I4 strategy. This will save you a lot of time!

5 How quickly can you adapt and change?

You should never take Industry 4.0 lightly. Something that is based on the 9 different pillars will always pose certain challenges. Small issues with certain aspects of I4 can bring the whole system down. This is why it is very important for your company to be adaptable. You need to be able to change processes on the fly and improve procedures. If you think that your job is done once you implement I4, you’re sorely mistaken.

6 Can you take a financial hit?

Lastly, you will also have to consider your exit strategy. No matter how much we may praise Industry 4.0, the sad truth is that some companies will not benefit from it. In fact, the whole process may become a big loss. If this is the case, you have to ask yourself in advance: “Am I prepared for this and can I take the financial hit that goes with it?”

How to prepare technical communications for I4?

Industry 4.0 will also affect the way we write and deliver information.

When implementing Industry 4.0, there are lots of things a company needs to do on the back-end. Not only do you have to address technical aspects, introduction of new software and systems, reconsider compliance processes, but you also need proper documentation, manuals and other content that will back up the whole process.

There are a few things you can do to adapt your technical writing to Industry 4.0.

First of all, as I4 products are often connected to the internet, a paper user manual is not the best way to provide the user with information. I4 enables you to create and deliver more intelligent information.

So what is Intelligent Information?

Intelligent information is, amongst others:

- efficient use of content processes, people, and technology.

- content that is scalable and can be reused.

- content that’s personalized, so it delivers most value for the consumer of the content: the right content is delivered to the right person at the right time, regardless of the device or channel that the consumer uses.

Software companies that develop technical authoring tools, such as MadCap, Adobe, Author-it, Schema, Fischer, Oxygen etc develop tools that enable you to publish the same content to several output formats, such as PDF and online.

This is done single source. In other words: the same content is being reused for several output formats.

When you create single source content, you can not only use the same content for several mediums, but you can also reuse the content for several related products.

Principles that software companies build on and that a professional technical writer should embrace to create 'smart' content that can be reused is topic based (structured) writing or DITA.

Also, the newly published 82079 standard for information for use integrated much of these principles.

This standard:

- gives requirements for the information management process;

- describes how you can use people efficiently by describing professional competencies

- describes how you can use technology (media and format) in order to digitise your information for use;

- gives requirements on structuring information. This enables you to scale, automate and reuse content;

- states that information should be delivered individualised, if possible.

Conclusion

Although there are many unknown variables and still quite a lot of challenges to overcome, which makes it really hard to assess whether or not your company can pull it off, investigating the possibilities of Industry 4.0 is an absolute must.

In order to make more or fewer sound decisions, you should first of all determine which pillar(s) might be of most importance for your industry or just your company.

Also, identify the risks for your company and how to mitigate them.

In the end, you know your business best,, what direction you want to go to and what Industry 4.0 related business decisions serves that best.

I hope that this guide will serve you as a solid starting point. Leave a comment below if you have any questions.

|

Ferry Vermeulen is a technical communication expert and director at INSTRKTIV. It's Ferry’s mission to create digital user instructions for all products in the world. Listen to the INSTRKTIV podcast on Spotify or read one of his latest blog articles. Linkedin I Spotify I YouTube I Facebook I Twitter |