How to CE Mark a Machine

24/04/2023 Law & Legislation

We specialise in creating user manuals for all kinds of products, including machinery. As the user instructions are part of the certification process, most of our clients are in the process of making sure that their machinery and the instructions comply with the legal requirements.

I think it is useful for companies selling machinery on the European market to have more insight in the CE marking process. That’s why we will talk about how to CE mark machinery in this podcast episode.

In this episode, I am talking with Paul Hoogerkamp, who specialises in assisting companies with the conformity assessment procedures of all kinds of products, such as machinery.

Listen to the interview below and make sure to subscribe to the INSTRKTIV’S INSANE INSTRUCTIONS SHOW on your favourite podcasting platform. You can find the free transcript of this episode on this page as well.

SOME TOPICS WE COVERED:

- 2021: A new Machinery Directive?

- How to identify if your product is a machinery

- What are CE-marking requirements for machinery?

- The process of CE marking machinery

- How can you get or obtain the CE mark for your machinery?

- How to conduct a risk assessment

- What should be in your technical file?

- How to draft your declaration of conformity

DO YOU WANT A USER MANUAL TEMPLATE THAT ALREADY CONTAINS THE LEGAL PARTS?

Take the shortest way to a compliant manual. We have developed user manual templates for machinery (EU and US) that contain all legal content.

Table of Contents

Introduction to CE Marking Machinery

How to identify if your product is a machinery

Partly completed machinery

The new Machinery Directive (2021)

What are CE-marking requirements for machinery?

Machinery Directive characteristics

Six steps to CE mark machinery

Step 1 : Identifying the directives for your machinery

Step 2 : Determining the requirements for your machinery

Step 3 : Determining the route to conformity for your machinery

Self-certifying machinery

Step 4 : Testing your machinery

Step 5 : Compiling a technical file for machinery

Conducting a risk assessment for machinery

Step 6 : Drafting the Declaration of Conformity for machinery

Introduction to CE Marking Machinery

Ferry: Hi, there. And welcome to the show. In this podcast, we're going to talk about how to CE mark a machine. As we specialize amongst others in creating user instructions for machinery, most of our clients are involved in the certification process of their machines. With the instruction handbooks that we create, we help to provide clear information on how to use a machine safely, efficiently, and effectively.

The instruction handbook plays an important role in the certification process. One of the purposes of the instruction handbook is to warn the user of certain product risks. Risks are determined by means of a risk assessment. Safety of machinery is regulated on a European level by the Machinery Directive. The Machinery Directive also gives requirements on the content of the user instructions.

As I think it's useful for companies selling machinery on the European markets to have more insight in the CE-marking process, we will talk about it in this podcast episode. Together with today's guest, I hope to provide practical tips on how to go through the CE-marking process yourself and self-certify your machinery.

In this podcast, we will discuss what does CE stand for on machinery, what are CE-marking requirements for machinery, the process of CE marking machinery, and the six steps to CE marking, how can you get or obtain the CE mark for your machinery, how to identify if your product is a machinery, how to conduct a risk assessment, what should be in your technical file, and how to draft your declaration of conformity.

My guest for today is Paul Hoogerkamp. He's one of the most well-known experts in the field of CE marking and machinery safety. He is owner of MECID, with which Paul advises on CE marking and product safety. He developed several CE marking-related tools, is author of several books on machinery safety and risk assessment, is trainer at the Dutch Standardization Institute (NEN) and chairman of several standardization committees such as the Dutch Machinery Committee. Welcome, Paul. What exactly is machinery?

How to identify if your product is a machinery

Paul: If we think in technical terms of machinery, we have certain ideas in mind, like a steam engine or whatever. But the machinery in respect of the legislation means that you have to dig into the details, what clearly is defined as machinery. And machinery is a wider terminology. So you have to go to the Machinery Directive itself.

And then you can go to, for instance, the scope of the Machinery Directive. The scope says if the directive is applicable for the product. It says it applies to machinery. Okay, that we know already. And then interchangeable equipment is regarded as machinery. Safety components are regarded as machinery. Lifting accessory, that means a sling, for instance, or a chain, that's machinery. Of course they have chains, ropes, webbings, removable mechanical transmission devices, and particle pieces. All is regarded as products related to the Machinery Directive.

Ferry: And that's all listed in the scope of the Machinery Directive.

Paul: Yeah, in the scope. And of course then you have the so-called exclusions or exceptive exemptions, but exclusions from the directive. That means, look, machinery falls outside the Machinery Directive, so you have to clearly check the whole Machinery Directive. And then there is a definition, and this gives you a definition.

But the definition is wide. That means if you have a machinery, for instance, and that's clearly an assembly, fitted or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components at least one of the most at which are joined together for a specific application.

So a mice trap, with a wooden bar and a spring etc., that means they're already in the scope of the machine. But do they mean that a mouse trap is a machinery? Of course there's more to be said about that. But yeah, it's a definition. It's a more juristic, generalized term.

Ferry: But it's important.

Paul: Yes. Essentially you have to define something. So if you have moving things in your product, then it could be that they fall into the Machinery Directive. So then you check the Machinery Directive and say, "Oh, well, it is moving." So when it is moving, I can say, "Is this specific equipment used in fairgrounds or amusement parks?" Yes. If it is, you're outside the Machinery Directive. You have to comply with all the other directives, of course, or legislation.

So let's first state the first, for example, requirement; that is 1) always there is a directive, yeah? That is rule number one. Always, there is legislation. Rule number 2): When there is no legislation, rule one applies. So think about that. That means there is some regulation. It could be the general product safety regulation. It could be for automotive, etc. But there is always some regulation there.

Ferry: Yeah. For example, when there is no CE marking directive, then the General Product Safety Directive applies.

Paul: That's fair, maybe applicable. But it could be also “other”. Automotive industry has automotive requirements. Airplane, so the industry for... just depends. Okay, but going back to the machinery, so if this Machinery Directive is applicable, then you are, according to definitions, which have quite a lot of separate definitions added to it, and you are not in the exclusions, done. Then you have a kind of machine, falling into the Machinery Directive.

Ferry: Okay. I will include a video in the transcriptions as well, explaining how you can identify whether you have machinery or not. And I think I heard some clicks, Paul. So I think you opened the Machinery Directive. Am I correct?

This video explains exactly how to use our Operator Manual Template to create your own operator's manual for machinery:

Paul: I had to already open it because the text on it is filled with dots and commas, you can learn it by heart, but it is not useful to learn it by heart. And sometimes, and even nowadays, I'm almost 35 years in this business, I even say, "Okay, what is the clear case?" It's heuristic. That means if you have to pinpoint each terminology, if it's okay.

So if it's a machinery, yes, it's machinery based on the definition, not in the exclusions and on the, yeah, let's say the terminology.

Ferry: And then, for example, I do see the following: For example, the exclusion of household appliances and ordinary office machinery. So, for example, we created user manuals for shredders, office shredders. And they obviously have moving parts, so you would say that they need to comply with the Machinery Directive, but they're excluded because they're seen as office machinery.

Office equipment is excluded from the machinery directive

Paul: And that describes a situation that has a historical background. I will not go into that detail. But you can have some guidance documents explaining what is, then, household equipment and what not. And you'll have an office machinery for printers and of course shredders can be household.

But don't be misguided by this situation because if there are moving parts, and under the low voltage, moving parts are also addressed, also chemicals, etc. So Low Voltage Directive is the so-called let's say harmonized directive that is let's say completely harmonized. That means that if it's fallen under low voltage, all hazards that are in the product are addressed.

Ferry: Also mechanical hazards.

Paul: Yes

Ferry: Because the risk analysis is mandatory for low voltage appliances, right?

Paul: Yes. Now in the latest issue, they put that in it. And otherwise they said, "Well, there are so many standards and this follows the standards, and then it's okay." But the risk assessment is nowadays part of it, and it's okay. It should be risk assessment addressed. It was already mentioned. The purpose was already there but not mentioned. And I think it's right to mention the risk assessment there.

Risk assessment

Partly completed machinery

Ferry: And the Machinery Directive also distinguishes partly completed machinery. Why is this a special group?

Paul: Yeah. Well, there was an early intention that machinery, what is not complete, literally complete because when is a machine complete? When it works at your premises; for instance, you have a printing machine. But there could be a part that is already moving and doing something, but there is no safeguarding, no nothing about it. So this is already in order the definition.

And so they made the kind of partly completed machinery because you cannot have a full technical file on that. You cannot have full safety on that name. But partly complete machinery is then evolved to something that everybody thinks that a halfway machine is also partly completed machine—not necessarily the case. It is what you bring on the market.

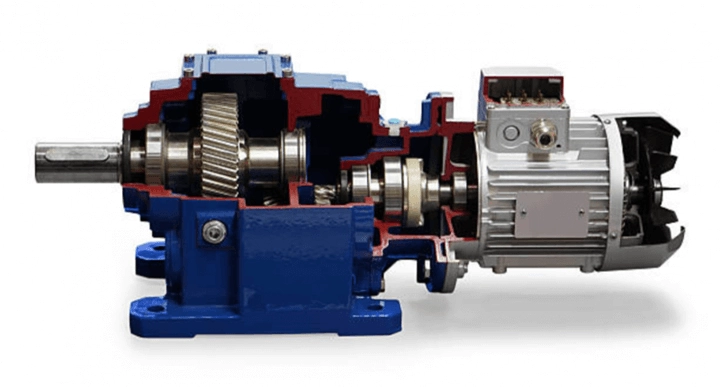

So if I have a drive system, that is the example they use here, if I have a drive system, it's a motor and a gear attached to it, maybe, or a motor itself, you can put a motor on a hydraulic motor, or an active motor, or the market. Like I tell you, on the magazine, you can sell it on the market.

So there are some moving parts on the market, which, related to machinery, yeah, what to do with it? They have no end function, let's say, but they're still machinery. Well, in that kind of category, they put this part to be completed machinery. Maybe in the future it will go out. Some ideas, I say really don't need partly complete machinery. It is either completed or not completed.

But in the declaration of conformity and the manual, there's enough explanation of how to get it right or get it safe. There's a lot of saying that we need it, the partly completed machinery, and we have to attach more stringent requirements for that.

There are two ways. And I don't know what it's going to be in the future, but I think partly completed machinery is a little bit degraded. You can do it also with the CE marking machinery and give a CE mark on the machinery and not talking about partly completed machinery at all.

The New Machinery Directive (2021)

Ferry: So talking about the future, because with the current Machinery Directive, it's from 2006, it's also named 2006/42/EC Directive, I think at the moment the European Commission is revising their Machinery Directive. Is that correct?

Paul: Well, I don't know if this at this moment will be done because they have a lot of things on their mind now. But yeah, there is on the way the idea of the successor of the old one. And that will be maybe not a directive but a regulation. But it's not final.

There should be in August 2020 a kind of draft. Well, it's almost August. So they say about 2021 there will be a new directive. I have to see it.

Ferry: 2021

Paul: Yeah. So next year. Well, don't believe it because the European Union has something else to do. We have for instance a Brexit problem. We have the General Product Safety Directive that needs to be renewed. It's already there; has to go to Parliament. But the Parliament is busy with other things, I think. We keep waiting.

Ferry: Okay. Before we dive into the contents of the Machinery Directive, I want to summarize what we just discussed because I think this is really practical information for the listeners. So let's say that I'm a manufacturer or I'm importing a product and I do have my doubts whether it is legally seen as machinery. So, Paul, please correct me if I'm wrong. So what I do, I just go to Google. I search for, for example, Machinery Directive or for 2006/42/EC.

I'll go to the website of the European Commission, which is, I think it's the EUR-Lex website, so EUR-Lex.europa.eu. I'll put the URL in the transcriptions. There I can find the Machinery Directive. I can download it for free.

EU Growth: https://ec.europa.eu/growth/single-market/european-standards/harmonised-standards_en

EU Growth/Machinery: https://ec.europa.eu/growth/single-market/european-standards/harmonised-standards/machinery_en

Ferry: In Article 1 when I look in the Machinery Directive, Article 1 is about the scope. I will see that this directive applies to machinery and some other things, like safety components and partly completed machinery. And if I do have any doubts, so, okay, yeah, clear: It applies to machinery. I already knew that.

But then I can go to definitions, which is Article 2. And there you can find the definition of machinery. And by reading and understanding the definition, you can determine if your product falls under the scope of this definition, and so if the Machinery Directive applies.

Paul: I would suggest also getting the royal way to this. I also prefer the shortcut. The shortcut is go to the site EU Growth. Then scroll down to the list box. Tick on machinery. And then you go straight to the site Machinery Directive and you can download them from the EUR-Lex site because they have authorizations.

But you also have the entry point of the guide to the Machinery Directive, giving you detailed information if the explanations are not very clear from the juristic point of view. Also it gives you a list of the standards. So your approach is okay, but this was the rough way and now you have entry points.

EU-Growth website

What are CE-marking requirements for machinery?

Ferry: Yeah, okay. Thanks for explaining that in more detail. And so let's say my machinery has some rotating parts, I'm checking the definition at the moment. So let's say my machinery is an assembly that’s fitted with a drive system. So yes, I do have a machinery. Then I know that the Machinery Directive applies. What does the Machinery Directive say? What kind of requirements will I find in the Machinery Directive?

Paul: Generally you can summarize the whole directive, do a proper risk assessment, and make safeguarding and protective measures. So that's basically the one-liner. But going into detail, you go to the general principles. And that gives you a risk assessment, how to do it later on. There are standards for it; one important one, by the way, EN ISO 12100.

But then there are, in the next annex, they're giving you requirements for several issues, like a control system, like ergonomics, like safeguarding and also manuals. So they give a lot of information in Annex 1. But Annex 1 has six chapters. And the general chapter is applicable to all machinery. The Chapter 2 is for special machinery, transportable, or you can carry those machines, or its hygienic requirements.

Paul: And then the third is for mobile. Four is for lifting, fifth for underground, and a sixth for the lifting of persons. So what you need then is depending on your product.

Ferry: Yeah, so you have to, again, when we go through the six steps of CE marking, then in step one, you need to identify the applicable directives and standards. And then in step two you have to study them and identify what applies to your machinery.

Paul: Yeah. So you first need to know what is your product and what is your function of the product? And then you go to this shortcut site, let's say EU.growth, and then pick the right directive. It could be plural. That means not only the Machinery Directive is applicable, but it could also be the RoHS Directive, the EMC Directive and so on, depending on the product.

Ferry: Yeah, noise emission.

Paul: Depending on then it is certain is the machinery for noise emission. But a part of the machines, like concrete, verticals, externals, and so on, have to have some requirement; that means clarification for sound emission.

Ferry: And you're saying so actually basically you can boil it down to the Machinery Directive says that you have to do a risk assessment. But another approach could be that you can say the Machinery Directive contains requirements on the design of a product, their user instructions, the technical file, the route to conformity, the declaration of conformity. Is that correct?

Paul: Yeah, that's correct. But, again, it is based on what the requirements are for designing your product. Let's say if you're a designer, you have to know the requirements of the Machinery Directive if you design a machine. If you're designing products, you will have to know the product requirements. It's basically if you have no requirements, as recall, the program of requirements, for instance, you have to comply with the user. The user wants a green product. So green is a specification. But that's a specification from the user. We have formed legislation specifications for machinery during Annex 1, pp Annex 1, etc. There are the requirements.

Paul: So you have requirements from a legal point of view. You have maybe requirements from standards, and you have user requirements that they want orange-colored face masks. If you want a face mask orange, yes, orange is not a requirement from a legal point of view. Yeah, but it could be that you're making a fiesta in the football stadium, and you have orange face masks. I don't know. It may be. But orange is a specification item.

So for your designing of the system, you need to know what to do. So this requirement, there should be in step two, determine requirements. That means not only the legal requirements, but all the requirements. And then you do a so-called requirement analysis.

Machinery Directive characteristics

Ferry: Yeah. What makes the Machinery Directive special? In other words, can you highlight some parts that the Machinery Directive contains that we won't find in other directives?

Paul: Yeah. Typical, regarding specific control systems, I think the Machine Directive is very special in certain control systems; that means control systems that are giving you high risk if the control system fails. Like, say, if the PLC fails or the electrical wiring fails, those control systems are addressed, a certain amount of control systems. That is typical. Safeguarding in general is more specific than in others, I think.

Ferry: Risk assessments.

Paul: Yeah, but risk assessment is general. You have to do it individual, all directives. The word risk assessment is applicable. The risk assessment is not specific for machinery. It's also risk assessment now in low voltage. Well, I can hardly imagine any directive that doesn't recollect something about risk assessment.

Ferry: Yeah. And if it's not mentioned in any other directive, then it's highly recommended to conduct a risk assessment. Paul, okay, so there are some things that distinguish the Machinery Director from other directives. And first of all, of course, it applies to machinery and not toys, etc.

Six steps to CE mark your machinery

Ferry: But there are also things similar; for example, the six steps to get to CE marking for your machinery. And although those six steps apply to all kinds of products, I interviewed you in another podcast episode, where we talked in more detail about the six steps towards CE marking for all kinds of products.

Step 1 : Identifying the directives for your machinery

Ferry: So if you're interested in the summarization of these steps, please listen to that podcast. When I want to CE mark my machinery, Paul, I start with these six steps, or I start with step one, identifying the directives. And we already briefly discussed that in the beginning. Shall we continue with this process which makes it really practical for people that want to sell machinery?

Paul: Okay. You have, let's think of a table salt machine, let's say. Yeah? You identify that an applicable directive is the Machinery Directive. Now you have to check all directives are applicable. Well, certainly the RoHS Directive is applicable and the WEEE, and of course the EMC, and nowadays everything is just Bluetooth and so on. So maybe they're already applicable, Radio Equipment Directive.

Paul: But anyhow, let's focus on this Machinery Directive. Then you go, if it has your product, kind of so-called C standards, it's the best way. That’s a standard that is let's say based on a product or a product group. Well, circular saws have a standard. Conveyor belts, standards, C types. But if you don't have a C-type standard, you can say, "Well, can we do it with the so-called B and A standards?" And of course the B standards are related to several safety subjects like electrical safety; there is a B standard: 60204. That's one word. 32 for hoisting equipment, any.

There's a specific standard for a specific technical requirement, technical issues. Let's say the electrical issue is covered by the so-called 6204, but we have hydraulic issues, which are subject to the 44134 hydraulic and 144 for pneumatic. So dependent on the use of the energy, we can have standards, and depending on the economic aspects, we can have standards and so on.

So first of all, you have to look to the C standards. If there's no C standard, go back to the B and always apply the A, which is called EN 12100 for risk assessment. So then you have the standards.

Ferry: Which is part of step one. So then I know if the directives have the standards. Is there any website that you can direct the listeners to where they can find these A, B, and C standards?

Paul: The best way is to go to the EU Growth and then to the Machinery Directive. It's, like, a table in the site, and then scroll down. And then you have a PDF file in the various languages. And you can download the so-called C standards.

Paul: You can also go to the DIN, BSI or something, a standardization institution. But you can find standards. And then you can see if it's a C, or a B, or an A standard. That is also a possibility.

Ferry: What I hear every now and then from companies approaching us is that they say, "Okay, we identified our standards because we did find the declaration of conformity of a competitive product on the internet."

Paul: Yeah. It's always possible to find. Google, internet, or something else. But then I would suggest the following: Check the standards, standards mentioned, the number. Put the number in, for instance, in the name for Dutch Institute or DIN. And verify if the number is applicable, a standard.

Ferry: And not withdrawn, meanwhile.

Paul: Yes, of course. It could be withdrawn. It could be a wrong number and so on. But how can you be assured that the declaration from your competitor is compliant and okay?

Ferry: Exactly, yeah.

Paul: There's another point. But you have a start point, okay, starting point.

Ferry: Yeah. And so I'm always a big fan of going to the source. So that's either the website or the official journal of the European Commission, for example, a standardization institute, where the up-to-date standards are listed.

Paul: Yeah, that's correct. So go always to, let's say straight go to the horse mouth, there where the directives are listed form the European Union and where the standards are coming from ISO, IEC, and of course European CEN-CENELEC, the standardization committee. But you go to the standardization committee in the member’s state itself, so in Germany, you go to the DIN. In the Netherlands NEN in France AFNOR, BSI and so on.

Step 2 : Determining the requirements for your machinery

Ferry: Okay. So that's step one. We've identified the directives and the standards. Then we go to step two. And that's actually determining the requirements that are listed there. So basically it means that you have to study on the directives and standards.

Paul: So the requirements that we have in step two, that means also not the legal requirements, but it can also be the requirements that are fitted to let's say the user. That means the color is green, yellow, or blue: color qualification. It could be a surface qualification. It could be a GUI, so layout for PC qualification that has nothing to do with safety or at least can interfere with safety, and then you have to do a so-called requirement analysis. And that is meant by step two.

Ferry: We're speaking about the CE marking process, here, but still you want to include other user requirements in this step.

Paul: Yeah, but it could be that the user requirements conflict with the safety requirements. And then you should be aware of that in your design process.

Ferry: Yeah, okay. Clear-

Paul: So I'll give this as an addition to this requirement because if you go only to legal, you're not designing a legal product, you're designing a product which complies to legal requirements.

Ferry: Okay. And for example, correct me if I'm wrong, and it's like in... Okay, so recently the ISO 20607 has been published, which is a standard for instruction handbooks for machinery. Well, sorry. Actually it's not completely harmonized. It's been partly harmonized.

And the part about the publication form is not harmonized. Why not? Because the ISO 20607 standard says that first of all you have to check what agreements you have with your client on the publication form, meaning that when your client does not require, for example, a paper user manual according to the standards, you would be allowed to provide an online manual if there is no specific national legislation or other legislation for that.

So could it be, for example, that when I have a client requirement, saying, okay, "No, we don't need a paper manual," that requirement is conflicting with, well, not per se the requirement in the Machinery Directive but definitely in the guide to application of the Machinery Directive because this guide explains that for the machinery... In order to comply with the Machinery Directive, you still need at least the safety instructions in a paper format.

Paul: That's correct. Step two is about not only determining the requirements but also determining conflicting requirements. And of course basic conflicting requirements, always the legislation wins this time. And yeah, the example you mentioned about the paper, and non-paper, and PDF, and what's the electronic way, yeah, the commissioning is now a little bit shifting about it, by the way.

But still the requirements are there. But there are industries that don't need paper. Really, I have industries with clean rooms, and paper is not allowed in a clean room. So you have to have another method. But the method is very clear. They have a PDF file on the screen. And they are not allowed to work if the screen is down, for instance.

But then you have system dedicated workers. But if there is a user somewhere with a normal machine, who does not have the possession of, for instance, the internet as direct reading safety signs or something like that. So that's why paper is still the one that is in legal terms on the machinery-active one.

But there are certain areas... They are thinking now of certain areas to exclude the manual paper version. That means that you have to provide an electronic way, and paper is then maybe not needed anymore.

Ferry: Yeah. For example, the 82079 standard actually says that the format of the manual or the medium should be based on the user's needs.

Paul: Yeah. But then, again, it's conflicting in part of the Machinery Directive, maybe in the new directive conflicting items are solved. But in general there is already one in the medical devices. You can electronically give information but it should be between professionals, clearly understandable, etc. But then there is a not-paper-manual approach.

Ferry: Exactly. And I think we can learn in another podcast episode about this topic. So, okay, step two, determining the requirements, means also looking at any conflicting requirements, which reminds me of the fact, of course, that a standard is not in most cases a mandatory thing to follow. So a standard is one way to meet the requirements of the directive. When you apply your standards, you create the presumption of conformity. So it does mean when the standard says it needs to be green, but your user requirement is that it should be orange, then when you have a good reason to choose something different, then you're free to do so. Is that correct?

Paul: Yeah. It sort of limits you’re free. Of course there’s always a limit or a boundary attached to it. But you're free to change the color. But remind me that sometimes the color is for signaling. And then-

Ferry: It gets safety related, yeah.

Paul: Yeah. So you have to prepare for changes or deviations from the standard. It's okay. But if the deviation is not safe enough, then it's not okay, of course. So you have to provide the equality that the solution you choose is equal or better than the solution suggested in the standards.

Ferry: Yeah, because otherwise you will be held liable if something happens.

Paul: Yeah, you will be held liable anyway, but you then have documentation to have general opposition against... so yeah, a lawyer or legislative system. Then you can say, "I followed the standards, and the standard gets me to put a sense of conformity. And I showed that this approach is equal. See my technical file, for instance."

Ferry: Yeah. Okay. Shall we go to step three, Paul?

Paul: Yep

Step 3 : Determining the route to conformity for your machinery

Ferry: Okay, so we've identified the requirements. Now in step three, correct me if I'm wrong, we have to determine the route to conformity.

Paul: Yeah. Well, if you know the route of conformity, then also go to the directive that is showing you certain machines that need enforcement of a notified body, is Annex 4. Is you machine, one of those machines? If yes, go to notified body, and then notified body check on NANDO if the notified body is performing the requirements and if the notified body is allowed to check on that part of the directive.

Ferry: Is it correct that there are actually three routes to conformity? So I thought there is an assessment of conformity with internal checks on the manufacturer of the machinery. There is EC-type examination and full quality assurance?

Paul: Yeah. And it could be applicable both or simultaneously, let's say, depending on the product. So if you have an assessment that only... until check is done on the documentation, okay, that could be fair enough. But it could also be that you have a type examination because the standard is not full detailed about this product, and there are parts that needed some clarification or there are some gaps in the standard that need clarification.

Ferry: Yeah. And the example of this circular sawing machine, circular-

Paul: Yeah, circular saw... Yeah.

Ferry: Right. So what route to conformity will apply to this machine?

Paul: Well, if there is... For circular saw of the specific type, circular saw, it's in full standard that's let's say covers all the requirements of the directive-

Ferry: C-Standards, you mean.

Paul: C-Sstandards, correct. Yeah. If there is for this particular saw that you mean, a full standard that covers all requirements of the directive, then you follow the standards and notified bodies. Only there is conformity in total for, yeah, let's say the technical file, then the standard is the one you follow.

Paul: But if the standard is lacking some points,... in the early stage, the beginning, there was as standard, for instance, for hedge-trimming machines, and for instance, the noise was not dealt with, so you had to do something with noise because machinery has to do something with noise. But it was not dealt with in the standard, so you have to go to a notified body. They measure it, and they say, "Okay. This is okay."

Paul: But if the standard is fully complied, telling you how to deal and how to do the measurement, you can, but the problem is, in this specific case, the experiment has to also comply with emission outdoors. But maybe there's an example for the circular saw that is not an emission outdoors and is purely if the standards covers all the requirements, then there is a notified body involvement is minimized to practically zero.

Self-certifying machinery

Paul: And if there are some parts that are dealt with, then the involvement is for that part, or even when there is no particular standard for it, you have to do a full check on the EC type examination, for instance. And type examination could mean also production process checks, not production, but also design process and dependent on the modules. So when choosing modules, they have to explain then the modules: Where are the modules? And the modules are A, B, C, etc. to the H model. And it means full quality assurance, design process, engineering process, production. It's all of emphasis, all parts that, for instance, is module A is self-certification. So there's a module there, I promise you.

Ferry: Okay. It still sounds like a lot of theory to me. But I think it's important. So, again, it depends on the type of machinery you have. And you have to study it yourself and identify what applies to your machinery.

Paul: That's correct. It sounds complicated, but it's not so complicated if you know that the machinery in itself has full compliance on the module, be an H, and depending on the type of machine. And I can assure you that 95% of the built machinery of your machinery has nothing to do with this module stuff, it's only let's say self-certification.

Step 4 : Testing your machinery

Ferry: Okay. And this self-certification, so the actual doing, conducting this self-certification is step four, so which is the testing of the machinery.

Paul: Yeah, but it's also regarding step one and step two, etc.

Ferry: Exactly. Yeah, sorry.

Paul: But... Yeah. And of course when there is in the standard, for instance, kind of testing, but there's the testing that means that when you have a requirement and there's also the Machinery Directive, that sound/noise measurement. Measurement, that means that you have to do some tests if your noise is okay. Vibration means measurement is okay, control systems, if you control certain functions, it's a kind of testing.

Ferry: Is the risk analysis, is that part of testing as well?

Paul: Yeah. You could say... I tested if you do the right risk assessment, yeah, this kind of testing. But of course to conduct a risk assessment, part of the game is on the line. It started at step one.

Ferry: Yeah, it should be in the technical files. That is step five. That should be done anyway, yeah.

Paul: Yeah. And if you start a risk assessment and then at a later stage, I don't think you have a proper process because all Machinery Directive-related items are going into the design process. It is a design that you have to do. Inherent design is the first above all, and safeguarding, and then of course get information. And it's not that the one is before the others, but inherent design means that you can really design out in safety.

Ferry: Do you need to document the testing?

Paul: Of course. If a test is documented, it should be documented in such a way, I wrote it also in books, a very simple checklist how to and what to do. But the documentation should be in this way, that if I see your document and do the same test with the same test equipment or the same alike test equipment-

Ferry: Under the same circumstances?

Paul: Under the same circumstances, I get the same results.

Ferry: Yeah, it should be clear to anyone who reads it.

Paul: And the report itself has you can make your own report in Word form or whatever form. But it starts with who is the tester? Who has witnessed the test? What is the test equipment? What is the collaboration of the test equipment? What is the environment, the temperatures, the pressure? I don't know, it depends on the test.

Ferry: Meaning that if there is a standard available for the testing, it's wise to use that standard.

Paul: The word ‘wise’, I should use the word ‘you shall use it’, because-

Ferry: It's highly recommended.

Paul: Yeah, highly recommended testing, so yeah.

Ferry: Okay. All right. Thanks. Anything else that you want to mention regarding the testing or shall we discuss step five, the compiling the technical file?

Paul: Yeah. One thing about testing, I see, for instance, there's a nice situation, a lifting beam. You have to do a test, for instance, for a lifting beam. It's a C standard. And the lifting beam requires that you should lift three times the load in a certain situation, and in other situations, two times load. It's in the standard. But let us show, you have to test a lifting beam with a workload limit of two tons, 2,000 kilos. And you have to test it. And you need a test of two times the working load. That means that you have to test it with 4,000 kilos.

Now, you can do a lot of things with chains and certified bags or what? It's very simple. Do the test, yeah? And how do you know if the... Do you... That was also the question: I need a certified hoisting device for it.

If you can measure it, if you are one centimeter above the floor with your bag full... I have a balloon full of water at 4,000 kilo. You already did some testing. So make the test not a test as for notified bodies, make the test with common sense.

Ferry: Yes, always use common sense.

Paul: Right. But common sense depends on who you are.

Step 5 : Compiling a technical file for machinery

Ferry: Okay. Thanks for explaining that in more detail, Paul. So then we've conducted all the testing, and then, which is part of the technical file, and in the next step of the CE marking process, which is the compiling the technical file, we put together all our evidence to prove that we have machinery that complies with the requirements of the Machinery Directive. What should be included, then, to the technical file for machinery besides the testing reports?

Paul: Well, the overview of what should be in the technical file is given in the Annex 7 of the Machinery Directive. The technical file for the machinery and even the technical file for the partly completed machinery, are listed in the annex, and they are not so deviating much from each other. It's about checking the compliance.

Ferry: Yeah. Okay. And one of the things listed in this annex that you have to include a copy of the instructions for the machinery.

Paul: Yeah. But that means that if the manual is lost, yeah, you can always say, "Yeah, sorry," to the labor inspection or the authorities, say, "Yes, the manual is lost." Well, your manual is not lost. Do you have a copy?

Ferry: Here it is.

Paul: Here

Ferry: Yeah, so the user instructions, you need to supply user instructions, a user manual with your machinery. And if you don't do so, you do not comply with the machinery directive. So actually you're not allowed to put this CE mark on the machinery. You're not allowed to draft and sign the declaration. And actually you're not allowed to sell the product yet.

Paul: That's correct, yeah, because you're not complying to one of these, and the usual manual is one of these requirements.

Ferry: And besides that, the Machinery Directive in Section 1.7.4.2, it gives really detailed requirements on the contents of your user instructions.

Paul: Yes. It's in general, by the way. It depends. I was in Brussels, and there were technical writers, and they said, "Well, each CE mark product needs a manual." Well, for machinery directive, I can go alone. But there is a kind of measuring device, yeah, measuring devices, and when you have a glass, for example a pint of beer, yeah?

Ferry: Yeah, a pint.

Paul: Yeah, that marking on it, on the glass itself, a marking, a CE marking, yeah, the notified body number. And I put this glass to this guy and said, "Do I need a manual for this?" You said just every CE mark item needed a manual, and I showed you there are sometimes situations that you don't need manuals.

Ferry: Yeah, exactly. But as another side note, this is my epiphany moment that I had because I did a few courses with you, so it was a course at the NEN about European legislation, which you were giving. And the machine, I think it was the Risk Assessment course you did.

And so in the beginning, I was like, "What? What is this all about?" CE Directive, of course I knew what it was in very low detail. But it was really complicated, and I can remember. So it was, like, 10 years ago I asked you a question: "So but why is there a CE mark on sunglasses?" And you said, "Because it's personal protective equipment." That was my first epiphany.

And the second one was when you gave a presentation somewhere and you had a picture of a pint with a CE mark on it. And then I was confused again. I was like, "What? Why does it contain a CE mark? It's such a low-risk simple product." And then you said, "Well, it's a measuring device, so it falls under the measuring device directive." And that was my second epiphany. And then it all started to get clear, right, that's how you look at directives, etc. But sorry, that's just as a side note.

Paul: Yeah, a glass of beer, manual for drinking beer.

Ferry: For sunglasses, maybe you need an instruction sheet with some safety reminders, but for a glass of beer, no, you don't need user instructions. In the Machinery Directive, in this 1.7.4.2 section, there is a list of, I don't know, maybe 20 or 30 requirements on the user instructions, but they are very general, as you just indicated. In order to create user instructions that comply with those requirements from the Machinery Directive, you can apply standards, for example, the 82079 and the recently partly harmonized ISO 20607 standards.

Paul: Yeah, but also look at when your project is in the C standard range. The C standard tells you also the extra needed parts for in the manual. For instance, it will tell you that the sound pressure level should be in the manual, that for instance the maintenance of the specific unit should be in the manual. So the type system gives you all of the information for use or makes remarks about it.

Ferry: Yes. Actually when you want to know what requirements are for the instructions for use for your machinery, you have to identify first of all the C standards. They're mostly there for I think it's, like, Chapter 4 or 5, which is about marking and instructions, seven, sorry.

And when you know that, the next step would be to see if there are any so-called vertical standards, for example, the ISO 20607. And then the next thing you have to do is to see if there are so-called horizontal standards that apply to a broader scope of products, for example, the recently published IEC/IEEE 82079.

Paul: Yeah. But the standard you mentioned about a manual, it's more horizontal. It's about manuals in general.

Ferry: The 82079.

Paul: Yeah. But there's IEC standards. It's not harmonized because of some points and partly harmonized the other one. But it's about what you have to incorporate into your manual, and that is in the C standard. So this specific signal, this warning signal, this should be in the manual or marking. That will give you a C standard. And of course in some B standards, also markings are there, generally electrical safety, 60204.

Conducting a risk assessment for machinery

Ferry: Yep. Okay. The last thing that I would like to discuss regarding the technical file is the risk assessment. And you already mentioned that there is a standard to conduct a risk assessment, which is the 12100. There is a process, right, in order to conduct a risk assessment for machinery.

Paul: Yeah. The risk assessment starts at zero. And then it is a so-called iterative, just a repeating process. And how the process is done is not specifically mentioned, but of course you should do a process with more discipline at the table, for instance, electrical, mechanical, and depending on the product, chemical. I don't know, but don't do it on your own because then you make mistakes that belong to your own.

Paul: So the risk assessment is done in the wider circle. But risk assessment is given, not the... yeah, let's say the way of acting how to do a risk assessment, but more given in the risk assessment there should be addressed the hazardous situation, the hazardous event, etc. And that is in Chapter 7 of the EN 12100.

So the points to address are as we mentioned, and sometimes the inputs are addressed, but the process itself, you can really boil it down to one-liners. And that is the simple thing “what if”?

Ferry: So, for example, when we talk about the sawing as a circular saw, then you can say, "Okay, what if the saw starts to rotate?"

Paul: Yeah, and when my head is nearby.

Ferry: And then, yeah, exactly, you can do that for mechanical hazards, electrical hazards, radiation hazards, ergonomic hazards, etc.

Paul: Every hazard. But now you have at least a very simplistic approach: What if? But that is also a nasty one because if I do a what-if with some knowledge about safeties and risk, it's otherwise done by someone who has not the knowledge about it and knowing “what-if”. So he's forgetting a lot of things.

Ferry: Yeah, but also when you as an external expert conduct a risk analysis, you don't have all the design knowledge yet. So it's always a combination of working together with a manufacturer, for example, isn't it?

Paul: Yes. That's correct. But the designing knowledge of the product itself is, at the manufacturer, I know, but the designing process, I studied it, by the way, is very familiar. But the what-if, you have to do a what-if or a structured way. And that can be a process. It's called, for instance, and FMEA (Failure Mode Effects Analysis. You can have an [?]] analysis, you have an inventory analysis.

And you have several ways of analyzing structural systems. And the what-if is of course boiled down to a simple statement, but the what-if needs to be in a structured way to be applied.

Ferry: Yeah, okay. Let's leave the risk analysis for what it is. We've been talking about the technical file, so the user instructions are part of the technical file. The risk assessment is still part of the technical file, the testing report and everything else that you can find in Annex 7 of the Machinery Directive. So when you're building the technical file, what you basically do as a manufacturer, you're completing your evidence, the evidence that your machinery meets the requirements from the Machinery Directive.

Step 6 : Drafting the Declaration of Conformity for machinery

Ferry: And as soon as this technical file is complete and you know for sure that your machinery meets all the requirements, you're free to go to step six. Is that correct, Paul?

Paul: Yeah, which is to draw up a declaration of conformity, either a declaration of incorporation, depending on partly completed machinery, etc. and declaration of performance for construction products. But you need to do some declaration. And the declaration you sign has to comply with certain rules, and rules are explained in the directive.

Ferry: Okay. And then I've drafted my declaration of conformity. And then I can sign it. And when signed, I can sell my machinery within the European Union.

Paul: Yep. You're all free to do.

Ferry: Great. All right. I think we've discussed a lot, Paul. So I would like to close this session. I want to finish with one last question. I think you mentioned a bit earlier that there was a new product, a general product safety directive that will come into force. I'm quite interested. What is this GPSD about, and what's the difference with the current General Product Safety Directive?

Paul: Well, there was a little bit of rewording in certain situations. And there is a paper already available on the internet, I think, that explains in more detail. But also a product that comes from Germany, Netherlands, etc. but what does it mean? Where does it come from? Is it built here, 60%, 70%, 80%, 10, 0, 1? So I can import it from China and put a label on it. And then it's produced in the Netherlands, but what does it mean? So this certification scheme is a little bit more detailed. And also the liability issues are more details.

Ferry: You're saying liability, but for liability, there's not a directive, right? It's a liability for defective products or regulation.

Paul: Correct. But the connection between it, I mean, not liability—responsibility was the correct term.

Ferry: Okay. Thanks. All right. And like the current General Product Safety Directive, it's really general, basically. It just says your product needs to be safe. When you sell a product, it needs to be safe. The new one is more in the details, so it's more, it describes the definitions better.

Paul: Partly. That's because it has to be scrutinized by Parliament, and then maybe it needs some fixes. So it can circle around for several months or years. I don't know. But there is a text ready for Parliament available on the internet. So you can see what small differences or big differences with this old one from 2005.

Ferry: I'll have a look, and I'll include the link in the transcriptions. Actually, I was lying to you, Paul, because I have another question, the last one. So we've talked about the new Machinery Directive. What will be the major changes in this new Machinery Directive? What can we expect?

Paul: Of course artificial intelligence and robotics are general issues. So think about a robot, and the robot is putting some parts together. So the robot is at your table, putting your coffee cup from left to right, so you can program this. But now the robot can be reprogrammed. And without knowing, the robot can learn itself not only to pick up the coffee from left to right, but also your phone. Now you enter the room, and you're thinking the robot is picking up your coffee, so you're outside with your hands. But you will pick up your phone. And the robot says, "Hey, wait a minute. I learned just phone." It picks your hand. So this is a kind of programming situation, and how to make this safe?

So a robot works within an envelope, but is the envelope still the safeguarding? It has its own... What is it? So you have to make more clarification about robotics. You have to make more clarification about artificial intelligence, self-learning, and that would be hazardous in the future, security part; it's not directly defined, but if security in a control system means that your control system is broken or not ready, and the control system is taken over by foreigners, then you look at hazards.

Ferry: Almost sounds like it's really hard to predict how technology is going to evolve and what to include in a new Machinery Directive. Is it based on current experiences of the industry, or does it also take predicted development into account?

Paul: We try to do predicted developments, but it is hard to say. So you have to think in generalist terms. And maybe 20 years later and we look back, they will say, well, we have forgotten to define. The problem is we think about our future in a certain way, but when you are there and looking back, you're not in a similar way thinking.

So it's hard to make predictive things within the Machinery Directive. So let's face the truth. When we're all here and looking back to the Machinery Directive in 1992, did we in the Machinery Directive think about robotic systems? No. Only pick-and-play systems were in the range.

Artificial intelligence, nobody thought about it. Even with building machines, do we think that the machine is large as a chemical plant? No. That was already emphasized: Make small parts. Make the machinery not as wide as the earth. Okay. Description is, again, is a laser? A laser is not a machine, but we have complete machines for laser beam generation.

And when we think about systems nowadays, we can only make an extrapolation to the near future, but to make a prediction for 10 or more years, well, I think it's quite challenging, and will it be in the directive? I don't think so. The directive is what we see in the nearby future: artificial intelligence, robotics, and so on.

Ferry: Yeah, well, thank you, Paul. I think we've discussed so many things. And I hope we've provided a clear overview of the process of CE marking and what companies should do to make sure that their machinery complies. Thanks again, Paul. Thanks for being an awesome guest, and hope to see you soon.

|

Ferry Vermeulen is a technical communication and compliance expert. He also is a parttime trainer at the Dutch standardisation institute (NEN). Listen to the INSTRKTIV podcast on Spotify or read one of his latest blog articles. Linkedin I Spotify I YouTube I Facebook I Twitter |

DO YOU WANT A USER MANUAL TEMPLATE THAT ALREADY CONTAINS THE LEGAL PARTS?

Take the shortest way to a compliant manual. We have developed user manual templates for machinery (EU and US) that contain all legal content.